Day :

- Biomass Conversion Methods | Biomass Applications | Production of Biofuels

Location: Bleriot 1

Chair

Lorena Pedraza

Universidad Iberoamericana, Mexico

Co-Chair

Magdalena Dabrowska

Warsaw University of Life Sciences, Poland

Session Introduction

Bill Powell

H2-Patent GmbH, UK

Title: Warsaw University of Life Sciences, Poland

Time : 12:00-12:30

Biography:

Bill Powell a retired chartered engineer convinced of the potential of biomass to supply huge quantities of fuel gas and provide a very substantial contribution to the energy needs of the United Kingdom. He have advised both Chris Huhne and Ed Davey who served as energy ministers in the coalition government. He have addressed several conferences such as the World Hydrogen Technology Convention (WHTC) 2011 in Glasgow, and several specialist conferences such as those hosted by the IET. He cooperate with H2-Patent in Germany.

Abstract:

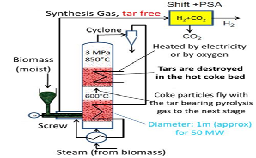

Thermal gasification can convert biomass to carbon neutral, or even carbon negative fuel gases, much more quickly and efficiently than anaerobic digestion. Applications include off-grid electricity generation, supply to the gas grid, and improved cooking stoves.

Such stoves use far less fuel and are far healthier than cooking over a three stone fire. Fuel can be agricultural waste instead of wood from forests. Biochar can be produced as a by product and used to restore soils depleted of carbon. There has been huge take up in China. Take up of such $10 stoves in Uganda is increasing from a low base at 50% p.a. The principles of operation are similar to larger gasifiers.

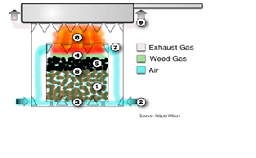

Instead of cooking, this pyrolysis gas can be used to generate electricity for a minigrid to provide lighting, phone charging and television after sunset. Other uses include pumping water or grinding corn in rural villages. The gas has to be cleaned to prevent contamination from tar causing frequent servicing. These gasifiers are best established in India but also used in Europe where there is waste woody biomass. They range up to about 500kW electrical capacity.

Engineers with experience of coal gasification propose biomass gasifiers that operate under pressure and use oxygen instead of air delivering over 50 MW (gas) to feed into the neighbouring gas grid. The pyrolysis stage described above is integrated with a higher temperature ‘steam reforming stage’ producing ‘syngas’ which is then converted into hydrogen or methane. Overall efficiencies of over 80% are forecast (hydrogen).

It is estimated that in this way UK biomass could satisfy 33% of current energy needs, but as for renewable electricity, incentives are needed. These in turn require a wider appreciation of the importance of ‘green’ fuel gas.

Recent Publication:

1 Wilson K Make your own biochar stove

2 Roth C Micro-gasification: cooking with dry biomass. Published by GIZ GmbH

3 Tetzlaff (2011) K-H Wasserstoff fuer alle

4 Day, Williams & Hodrien (2013) Low carbon gas from mixed waste, biomass and coal: a low cost route to CCS. Carbon Capture Journal

5 Buchholz, Da Silva & J Furtado (2012) Electricity from wood-fired gasification in Uganda - a 250 and 10kW case study. IEEE Xplore

Lorena Pedraza

Universidad Iberoamericana, Mexico

Title: Convenient product distribution for a lignocellulosic biorefinery: optimization through sustainable indexes

Time : 12:30-13:00

Biography:

Lorena Pedraza is a full-time professor at Universidad Iberoamericana’s Department of Engineering and Chemical Science. Her areas of expertise include fermentation technology, enzymatic catalysis, bioreactors and bioprocesses design. Her current research focuses on the application of biomass in bio-refineries and some examples of those current works include the production of xylitol, lactic acid, and ethanol from corn cob and municipal solid waste. Additionally, along with a multidisciplinary group from Universidad Iberoamericana, Mrs Pedraza is performing an analysis of the economic and sustainability aspects of the bio-refineries through modelling and process optimization. As part of her professional background, Mrs Pedraza was part of a research and development firm where she was in charge of escalating the production of an enzymatic biocatalyst. She is also a member of the Mexican Biotechnology and Bioengineering Society, the Bioenergy Thematic Network, and the Mexican Bioenergy Network.

Abstract:

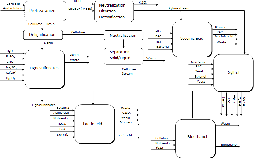

Lignocellulosic biomass can be employed to generate diverse chemicals, even though it has been mainly used as fuel. In Mexico, the main source of lignocellulosic materials are agricultural wastes, for example, residues obtained from corn, which is the main agricultural product in the country. Although corn stover is employed as animal feed and corn cob as fuel in rural communities, both residues are underused, which boosts their accumulation as wastes. It is estimated that 4 million tons of corn cob were generated in

2016. Such residue was proposed as raw material in a biorefinery for production of bioethanol, enhancing its applications and decreasing pollution derived from its accumulation. Nevertheless, the preliminary techno- economic analysis showed that the project was not feasible; therefore, generating diverse chemicals like lactic acid, succinic acid, xylitol and lignosulfonates, was considered. These products were selected according to their demand in the country. A multi objective optimization approach was employed to find an optimal product distribution for the biorefinery shown in Figure 1 that cope with economic (EPI), environmental (RSEI) and safety (SI) indexes. Through this strategy, an efficient solution with an EPI of 0.16 is achieved, generating an annual utility of 70 kUSD when xylitol and bioethanol production are favored over succinic acid and lactic acid. This tool can be applied with different feedstocks and products in a biorefinery scheme, with kinetic and yield data for corresponding processes.

Recent Publications

1. K. Fredga, K. Mäler (2010) Life Cycle Analyses and Resource

Assessments. Ambio. 39:36â€41.

2. L. Pedraza, A. Flores, H. Toribio, R. Quintero R, S. Le Borgne, C.

Mossâ€Acosta, A. Martinez (2016) Sequential Thermochemical Hydrolysis of Corncobs and Enzymatic Saccharification of the Whole Slurry Followed by Fermentation of Solubilized Sugars to Ethanol with the Ethanologenic Strain Escherichia coli MS04

BioEnergy Res. 9:1046â€1052.

3. G. J. Ruizâ€Mercado, R. L. Smith, M. A. Gonzalez (2012) Sustainability indicators for chemical processes: I. Taxonomy. Industrial & Engineering Chemistry Research. 51:2309â€2328

4. S Mussatto, J. Moncada, I Roberto, C Cardona (2013) Techno†economic analysis for brewer’s spent grains use on a biorefinery concept: The Brazilian case. Bioresource Technology. 148:302â€310.

5. Q Li, D Wang, Y Wu, W Li, Y Zhang, J Xing, Z Su (2011) One step recovery of succinic acid from fermentation broths by crystallization. Separation and Purification Technology. 72(3):294â€

300.

Magdalena Dabrowska

Warsaw University of Life Sciences, Poland

Title: Strength properties of pellets with addition of calcium carbonate obtained in pressure agglomeration process

Time : 13:00-13:30

Biography:

Magdalena Dabrowska is a Doctor in Agricultural Engineering. She is a researcher at position of Assistant at the Faculty of Production Engineering, Department of Agricultural and Forest Engineering at Warsaw University of Life Sciences – SGGW. Her main interests are renewable energy sources, especially pressure agglomeration of biomass, properties of biomass, energy plants, wastes from agriculture and industry, farm machinery. She is an author or co-author of 15 research papers in peer-reviewed journals, 14 conferences materials, co-executive in 4 research projects and in 1 EU project.

Abstract:

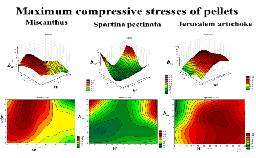

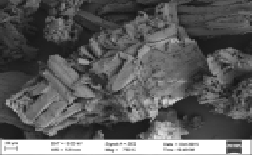

The scientific aim of this study was to gain a new knowledge and explain the impact of applying the addition of calcium carbonate to the biomass of different moisture content on selected evaluation measures of the produced pellets. The research material from three energy plant species: Miscanthus giganteus, Jerusalem artichoke and Spartina pectinata was characterized by using standard testing methods. The main research was carried out on the special stand with heating head and cylindrical opened chamber with 8 mm diameter with controlled temperature. The effect of 5, 10 and 15% addition of calcium carbonate on densification of the plant material with different moisture content was examined. Tests were carried out in order to select the best densification parameters, which turned out to be: mass portion 0.1 g, head heating temperature 140°C, the thickness of the die 60 mm. To determine the pellets quality the compressive strength analysis was conducted. Pellets were tested on the universal testing machine. It was found that the optimum strength was characterized pellets from Miscanthus and Jerusalem artichoke biomass with addition of 6–12% of calcium carbonate and respectively, 10–22% and 18–28% of plant material moisture. In the range of 10–30% of Spartina pectinata moisture content, the addition of calcium carbonate did not influence on the strength parameters of the pellets. Pellets made of Miscanthus material were the most durable. It was also stated that the amount of calcium carbonate depends on the specific physico-chemical characteristics of biomass.

Recent Publications

1. DÄ…browska-Salwin M., Raczkowska D., ÅšwiÄ™tochowski A. (2017) Physical properties of wastes from furniture industry for energy purposes. Agronomy Research 15(2), 388–394.

2. Lisowski A., Buliński J., Gach S., Klonowski J., Sypuła M., Chlebowski J., Kostyra K., Nowakowski T., Strużyk A., Świętochowski A., Dąbrowska-Salwin M., Stasiak P. (2017) Biomass harvested at two energy plant growth phases for biogas production. Industrial crops and products, 105, 10-23, DOI: 10.1016/j.indcrop.2017.04.058.

3. Lisowski A., Kostrubiec M., Dąbrowska-Salwin M., Świętochowski A. (2017) The characteristics of shredded straw and hay biomass. Part 1: whole mixture. Waste and Biomass Valorization, DOI: 10.1007/s12649-017-9835-y.

4. Lisowski A., Kostrubiec M., Dąbrowska-Salwin M., Świętochowski A. (2016) The characteristics of shredded straw and hay biomass. Part 2: the finest particles. Waste and biomass valorization, DOI: 10.1007/s12649-016-9747-2.

5. Dąbrowska-Salwin M., Lisowski A., Kostrubiec M., Świętochowski A. (2016) Pressure agglomeration of biomass with addition of the calcium carbonate. Proceedings of International scientific conference Engineering for rural development, 542-546.

Group Photo

Lunch Break 13:30-14:15 @ RBG

Shatrughan Soren

Indian Institute of Technology (Indian School of Mines), India

Title: Characterization and application of biomass used in metallurgical sintering operation as a fuel replacement

Time : 14:15-14:45

Biography:

Shatrughan Soren is Assistant Professor in Department of Fuel and Mineral Engineering, Indian Institute of Technology (ISM) Dhanbad, India, working in the field of biomass applications in metallurgical sintering operations. He has keen interest in Iron Ore sintering and pelletization process, so he is trying to synchronize an energy required process with biomass to modify the conventional method. His recently published article (Jha and Soren, 2017) is a detailed review about the work done so far in the field of biomass applications.

Abstract:

The The present paper highlights important aspects of sintering process for iron ores, which has been gaining considerable attention over the years. Increasing requirement of steel, depleting sources of iron ore, compositional variations, such as, decreasing Fe content, increased alumina, silica LOI and goethetic content as well as excessive generation of fines are some of the major factors behind growing use of the sintering process. Moreover, with environment policies becoming more stringent all over the world, there is an emphasis on containment of excessive generation of NOx, SOx and COx gases. Biomass has certain characteristics which makes it a potential alternate and that are, lesser sulphur and ash content, availability in plenty, lower generation time, uniform ignition but for smaller time period, lesser emissive constituents and carbon neutrality. According to literature, a metallurgical sintering operation can optimally replace 20% of coke breeze by biomass without effecting the quality of the product. The objective of the present work is to characterize biomass to find out its suitability and replacement ability in metallurgical sintering operations. Various analytical methods such as macro thermos-gravimetric analysis and micro TG-DTA, FESEM-EDX, FTIR is used to interpret the characteristics which makes it suitable for replacement.

Re

Recent Publications:

1. Jha, G., and Soren, S. 2017. Study on applicability of biomass in iron ore sintering, Renewable and Sustainable Energy Reviews, Vol 80: 399-407

2. Demirbas, T., and Demirbas, A. H. 2010. Bioenergy, Green Energy. Biomass and Biofuels. Energy Sources Part A. Vol 32:1067-1075.

3. Vassilev S. V., Vassilev C. G., Vassilev V. S. 2015. Advantages and disadvantages of composition and properties of biomass in comparison with coal: An overview. Fuel 158:330–350.

4. Zandi M, Paheco MM, Fray TAT. Biomass for iron ore sintering. Miner Eng., 2010; 23:1139–45.

5. Abreu G. C., de Carvalho J. A., Jr, da Silva B.E.C., Pedrini R.H. Operational and environmental assessment on the use of charcoal in iron ore sinter production. J. Clean Prod 2015; 101: 387–94.

Nwabunwanne Nwokolo

University of Fort Hare, South Africa

Title: Performance evaluation of a custom built waste heat recovery unit attached to a gasification plant

Time : 14:45-15:15

Biography:

Nwabunwanne Nwokolo research interests focus on biomass gasification and renewable energy in the institute Fort Hare Institute of Technology.

Abstract:

Johansson biomass gasification system is a standalone power generation system as it utilizes the syngas produced from the downdraft gasifier in an internal combustion gas engine for power generation. The syngas exiting the gasifier and entering the cyclone dissipates heat on the body of the cyclone due to the high temperature at which it exit. In addition this same syngas undergoes some cooling process at the gas scrubber before reaching the gas engine. As the gas engine drives the synchronous generator for power generation, some of the un-combusted gases exit through the exhaust pipe at high temperatures. All these add-up as waste heat within the gasification system, hence there is a significant opportunity for waste heat recovery in Johansson biomass gasification system. Therefore the aim of this study is to design and construct a waste heat recovery unit (WHRU) so as to harness the heat dissipated on the body of the cyclone for water heating. The design of the WHRU was made using an inventor based on the specifications of the cyclone dust collector. The WHRU was constructed using H R sheet commercial quality of dimensions 3 x 2,500 x 1,225 mm and angle equal commercial quality of dimension 30 x 30 x 2.5 mm. The performance evaluation of the WHRU was conducted at difference conditions and discussed. Result showed that the temperature of water in the WHRU could be raised from 20 °C to 78 °C without water withdrawal. Furthermore a maximum outlet water temperature of 65 °C was recorded with water withdrawal at a rate of 1litre/min or 0.02 kg/sec. More also the standing loss realized at this maximum temperature was approximately 2.11 kW/h. A maximum temperature of about 130 °C was recorded at the engine exhaust pipe which represents a significant opportunity for heat recovery with a thermoelectric generator.

Break:

Networking and Refreshments Break 15:15-15:35 @ Breakout Areas

Amin Ullah Jan

Shaheed Benazir Bhutto University, Pakistan

Title: Potassium and Zinc increase tolerance to salt stress in wheat (Triticum aestivum L.)

Time : 15:35-16:00

Biography:

Amin Ullah Jan works in the Department of Biotechnology as Faculty of Sciences in the Shaheed Benazir Bhutto University

Abstract:

Potassium and zinc are essential elements in plant growth and metabolism and plays a vital role in salt stress tolerance. To investigate the physiological mechanism of salt stress tolerance, a pot experiment was conducted. Potassium and zinc significantly minimize the oxidative stress and increase root, shoot and spike length in wheat varieties. Fresh and dry biomass were significantly increased by potassium followed by zinc as compared to control C. The photosynthetic pigment and osmolyte regulator (proline, total phenolic, and total carbohydrate) were significantly enhanced by potassium and zinc. Salt stress increase MDA content in wheat varieties while potassium and zinc counteract the adverse effect of salinity and significantly increased membrane stability index. Salt stress decrease the activities of antioxidant enzymes (superoxide dismutase, catalase and ascorbate peroxidase) while the exogenous application of potassium and zinc significantly enhanced the activities of these enzyme. Significant positive correlation was found of spike length with proline (R2 = 0.966 ***), phenolic (R2 = 0.741*) and chlorophyll (R2 = 0.853**). The MDA content showed significant negative correlation (R2 = 0.983***) with MSI. It is concluded that potassium and zinc reduced toxic effect of salinity while its combine application showed synergetic effect and significantly enhanced salt tolerance.

Pratik Desai

University of Sheffield, UK

Title: Solving the ammonia –carbon dioxide cycle – sustainable biomass utilization linked to a circular economy approach

Time : 16:00-16:30

Biography:

Pratik Desai is a 1st Class-Honours Chemical engineer (MEng in Chemical engineering with Fuel Technology) and PhD in Chemical Engineering at the University of Sheffield. He is the R&I Director at Perlemax and has extensive experience in microbubble generation, visualisation, fluid dynamics, interfacial dynamics and phenomena, non-equilibrium thermodynamics, fluidic and reaction catalysis. He is co-inventor of the Desai-Zimmerman Fluidic Oscillator, the Microbubble Mediated Ammonia Recovery process- 'Waste Factory', self-actuated wastewater aeration product (TOAD), nanobubble generation and associated applications in several sectors including biomedical and medical applications. He is the inventor of an energy- efficient micro/nanodroplet generation.He has led and developed several projects for aquaculture, aquaponics, hydroponics, novel contacting systems, bioreactors, chemical reactors with regenerating interfaces. Projects he is leading include bagged microbial reactors & fermenters, anaerobic digestion, biodiesel generation and worked on CO2 capture and utilisation using MEA and Ionic Liquids and desorb them using a novel microbubble unit operation (Desai-Zimmerman contactor).

Abstract:

Microbubbles are bubbles sized between 1µm and 1000µm and offer tremendous advantages with respect to transport phenomena due to their high surface area to volume ratio [1]. Accelerated biogas production rate via periodic CO2 microbubble injection was demonstrated with over 100%-120% increase in the rate of biogas yield for an untreated wet food waste in an anaerobic digestion process [2]. Recently, Desai et al [3, 4] demonstrated a new unit operation –microbubble stripping – in order to separate ammonia from an ammonia rich wastewater stream 300 times faster than an industrial stripping column with a mass transfer coefficient 3000-15000 times faster than a stripper. [5,6]The removal rate was as high as nearly 100% from the wastewater. This process, when combined with the accelerated biogas production introduces the third novelty of generating precipitated salts of ammonium carbamate and ammonium carbonate by reacting the CO2 and NH3 in water which can be selectively tuned - another feature not observed in literature - and is performed at room temperature and pressure. This reaction is exothermic and using heat from the exothermicity of this process to conserve the heat for the anaerobic digester is part of process integration. The theory proposed for the increase in biogas production rate is that the CO2 bubbles provide a pH shock to the system. The biogas generated from the anaerobic digestion is then sweetened from the sustainably sourced ammonia from ammonia rich waste water (which reduces liabilities for liquids like centrate and leachate for waste management companies or increase capital efficiencies for digestate by reducing ammonia inhibition and increasing solids loading). This results in enhanced methane as a product from the digester, which coupled with a smaller CAPEX from the increased biogas yield rate and reduced OPEX due to the heat conservation reduces digester payback from 8y to 2y.

Recent Publication:

[1] Brittle, S.; Desai, P.; Ng, W. C.; Dunbar, A.; Howell, R.; TesaÅ™, V.; Zimmerman, W. B. Minimising microbubble size through oscillation frequency control. Chemical Engineering Research and Design 104, 357-

366.

[2] Al-mashhadani, M. K. H.; Wilkinson, S. J.; Zimmerman, W. B. Carbon dioxide rich microbubble acceleration of biogas production in anaerobic digestion. Chemical Engineering Science 2016, 156, 24-35.

[3] Desai,P., Turley,M., Robinson R., Zimmerman, W.B., Ammonia removal from wastewaters by hot microbubble injection in thin liquid layers, [ in prep, will be submitted in time for conference]

[4] Desai, P. D., Zimmerman, W.B. Hot microbubble injection in thin liquid layers for ammonia-water separations. In The 68th Annual Meeting of the American Physical Society - Division of Fluid Dynamics, Jose Gordillo, U. d. S., Ed.; APS: MIT, Boston, Massachusetts USA, 2015; Vol. 60.

[5] Kamaruddin, M. A.; Yusoff, M. S.; Aziz, H. A.; Hung, Y.-T. Sustainable treatment of landfill leachate. Applied Water Science 2014, 5 (2), 113-126.

[6] B, S.; Beebi. Sk, K. Bioremediation of Ammonia from Polluted Waste Waters- A Review. American Journal of Microbiological Research 2014, 2 (6), 201-210.

Raid Mohammed A. Alrefai

Dublin City university, Republic of Ireland

Title: Integration approach of anaerobic digestion and fermentation process towards producing bio-gas and bio-ethanol with zero waste: technical

Time : 16:30-16:55

Biography:

Raid Mohammed A. Alrefai is an PhD researcher in Dublin city university DCU. My research interest is to investigate the integration approach of anaerobic digestion with another biomass conversion process in order to solve the environmental and economical issues associated with anaerobic digestion when it is applied at large scale. The integration approach has recently taken its shape but more investigations on it are still required.

Abstract:

The rapid increase in the world population has caused an enormous increase in the demand of energy. Growing demand has resulted in a shortfall in conventional energy resources. Due to that and because of the major negative impacts of fossil fuel on the environment and other aspects as well, the necessity toward finding alternative cheap, renewable, and environmentally friendly energy resources has significantly arose. Biomass as an energy resource has a potential to be a good alternative for non-renewable energy resources. Anaerobic digestion process is one of the most commonly biological conversion process used in converting biomass into biofuels. It has been extensively applied in many studies for converting several types of feedstocks and has proved it's significant effectiveness. (AD) digestates are generally composed of solid and liquid streams. Those streams are rich in nutrients and contain undigested materials which have not been digested in the digestion process. Despite the significant effectiveness, it would contribute in major issues if it has been applied at large scale, as the amount of digestates which would be generated are quite high. Due to that and to take an advantage of the digestates in the production of biofuel and bioproducts as well, the interests in enhancing and utilizing anaerobic digestion residues have recently much increased. Bioethanol is one of the most promising liquid biofuel. It is eco-friendly alternative to fossil fuels. In recent years, number of studies have investigated the integration approach of producing biogas and bioproduct in which would result in zero waste. However, this paper discusses mainly an integration approach for producing two promising renewable energies can be utilized in many applications with no waste generated. This approach is still at an early stage and require further studies to improve the properties of the biofuels and high-value bio-based products produced.

- Biomass Energy Resources | Pyrolysis | Renewable Energy

Location: Johnson

Chair

Robert Helleur

Memorial University of Newfoundland, Canada

Co-Chair

Marcelo Maciel Pereira

Universidade Federal do Rio de Janeiro, Brazil

Session Introduction

Tony Tiyou

Renewables in Africa, UK

Title: Bioenergy industry prospects in Africa

Time : 12:15-12:45

Biography:

Tony Tiyou holds a triple Engineering Master’s Degree from Cranfield University (UK), Ecole Centrale de Lille (France) and Faculte Polytechnique de Mons (Belgium). Tony also holds qualifications as Renewable Energy expert from the European Energy Centre (UK). After having worked and held various positions and roles for about a decade in both the Automotive and the Renewable Industry, Tony has founded with a partner, a consultancy, O’wango & TT Smart (O&TT). In September 2016, he launched a blog: Renewables in Africa.

Abstract:

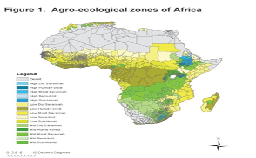

Background: Africa is endowed with vast renewable energy resources that can provide solutions to the severe energy issues the continent is experiencing. Among them, hydropower stands as the cheapest of all and has historically being the most exploited. Since the last decade, the continent is increasingly turning to solar PV and wind to bolster energy security and support rapid economic growth in a sustainable manner. This has been due in large part to improving technology and declining costs of equipment. In comparison, bioenergy which is currently widely used for cooking and heating is almost untapped as far as power generation is concerned.

Resources: At the difference of widespread solar, bioenergy is only present in large quantities in specific areas where rain is abundant, like Central Africa and parts of West and East Africa. Although less well-off, North Africa and Southern Africa are nevertheless looking as well at harnessing this energy to enhance the diversification of their energy mix. Across Africa, the technical potential for the use of bioenergy for power generation is estimated at 2.631 TWh, with 60% in Central Africa. Bioenergy is usually being exploited in one of its three forms: solid biomass, biogas and biofuels.

Market Opportunities: The current market in Africa is still in burgeoning stages. Investments and technologies have essentially been the main obstacles. Kenya has been experimenting biogas for few decades. Although they have been unlucky so far, they are still pursuing their development. Other countries like Senegal, Burkina Faso, Mauritania and Ethiopia have also express interest into the industry. Estimates suggest that South Africa could generate 5% of its electricity from biogas. Should it be exploited through the REIPPP, this will have the potential to transform the whole industry on the continent, like it has been the case for solar and wind.

Recent Publications

1. IRENA, Prospects for the African Power Sector

2. IRENA, AFRICA POWER SECTOR: Planning and Prospects for Renewable Energy

3. IRENA, Estimating the Renewable Energy Potential in Africa

4. IRENA, Biomass Potential in Africa

5. AFREA (Wold Bank), Wood-Based Biomass Energy Development for Sub-Saharan Africa

6. Klas Sander, Wood-Based Biomass Energy in Sub-Saharan Africa: Issues & Approaches

7. Belynda Petrie, South Africa A case for biomass?

8. Belynda Petrie and Duncan Macqueen, South African biomass energy: little heeded but much needed

9. http://www.ipsnews.net/2016/05/biomass-could-help-power-africas-energy- transition

10. http://www.wur.nl/en/show/Opportuniti es-Map-predicting-possible-crop- production-1.htm?wmstepid=mail_de_auteur

Marcelo Maciel Pereira

Universidade Federal do Rio de Janeiro, Brazil

Title: Making a bridge between biomass and hydrocarbon in a standard refinery

Time : 12:45-13:15

Biography:

Marcelo Maciel Pereira is an Associate Professor at the Chemistry Institute of Federal University of Rio de Janeiro (UFRJ - Brazil). He obtained the MSc and the Ph.D. in Chemical Engineering at Federal University of Rio de Janeiro. His research interests focus on kinetics and catalysis, hydrocarbons, biomass conversion, zeolites, CO2, greenhouse gas emissions and sequestration.

Abstract:

A conventional refinery is based on mature processes that obtain standard products from a large variety of non- renewable feeds. Despite enormous benefits to modern civilization,3 the adopted production and consumption patterns paradoxically put us at environmental risk. Therefore it is mandatory a paradigm shift to decrease the carbon footprint without reducing the energy access to people. Biomass is composed of functionalized biopolymers (lignin-cellulose) based on sugars- and phenol-derivatives. On the other hand, refinery processes have been designed to operate on poorly reactive compounds like hydrocarbons. The bridge between these two remarkable worlds was archived in two steps: 1- by transforming the biomass into a bio-crude, which was produced by ketalyzation in acetone [1, 2] and acetylation reactions in acetic anhydride [3] under mild temperature conditions (around 100oC). This black bio-crude (density around 1.0-1.3 gmL-1 and CHO composition of 60, 8 and 32 respectively) is chemically distinct of any other bio-feed so far. 2 -The transformation of bio-crude and model compounds by the fluid catalytic cracking and hydrotreatment into monoaromatic and saturated hydrocarbons respectively [4]. Herein the results of the fluidized bed pilot plant in laboratory scale of both model test and bio-crude are presented. For instance, a representative ketal-derivative, 1,2:5,6-di-O- isopropylidene-α-D-glucofuranose (DX) mixture up to 50% in n-hexane achieved three main goals: small coke formation, remarkable selectivity to hydrocarbons and slight improvement in n-hexane conversion as presented in Table 1. Moreover, no oxygenated compounds were observed in the liquid phase, thus resulting in a drop-in fraction in the fuel pool. The bio-base economy derived from this concept fits the requirements to be produced, transported and processed like wise to the up- to downstream in the oil industry. Finally, as a consequence the bio-crude behaves like hydrocarbons under realistic refinery process, oil could be partially substituted by bio-crude or, in the future; an entirely green refinery could operate using renewable feeds.

|

|

Coke cat. |

Yield |

Sel. Ar. |

n-C6 conv. |

||

|

Gas |

Liquid |

Coke |

||||

|

n-C6 |

4.8 |

20 |

68 |

16 |

13 |

|

|

30% DX |

6.4 |

22 |

66 |

19 |

50 |

|

Recent Publications

[1] N. Batalha, A.V.d. Silva, M.O.d. Souza, B.M.C.d. Costa, E.S. Gomes, T.C. Silva, T.G. Barros, M.L.A. Gonçalves, E.B. Caramão, L.R.M.d. Santos, M.B.B. Almeida, R.O.M.A.d. Souza, Y.L. Lam, N.M.F. Carvalho, L.S.M. Miranda, M.M. Pereira, Gasoline from Biomass through Refinery-Friendly Carbohydrate-Based Bio-Oil Produced by Ketalization, CHEMSUSCHEM, 7 (2014) 1627–1636.

[2] R. Garrett, T.G. Barros, M.O. de Souza, B.M.C. da Costa, M.M. Pereira, L.S.M. Miranda, Unveiling the chemical composition of sugar cane biocrudes by liquid chromatography-tandem mass spectrometry, Energy & Fuels, 29 (2015) 8082-8087.

[3] J.A.C. Durange, M.O. de Souza, M.R.L. Santos, M. Nele, E.B. Caramão, N.M.F. Carvalho, M.M. Pereira, Valorization of Sugar Cane Bagasse and Jatropha Curcas Cake: Production of a Biocrude by Acetylation Reaction under Microwave Radiation, Energy & Fuels, 29 (2015) 917–921.

[4] N. Batalha, J. Pinto, H. Ferreira, D.C. Baptista, L.S.M. Miranda, M.M. Pereira, Biohydrocarbons Production under Standard Refinery Conditions by means of a Representative Ketal Compound of Biocrude, Energy Technology, (2016) DOI: 10.1002/ente.201600313.

Lunch Break 13:15-14:00 @ RBG

Miguel Godino Garcia

UPM, Spain

Title: Moringa oleifera crop residues as a source of bioethanol

Time : 14:00-14:30

Biography:

Miguel Godino García is a professor at the School of Forestry Engineers of the Universidad Politécnica de Madrid. He has been involved in cooperation projects in Colombia for 8 years, promoting the integral development of moringa cultivation and its different uses, focusing on the production of moringa oil. In collaboration with the University of Tolima, it is being promoted the creation of a university network with different Colombian universities opened to other universities.

Abstract:

Moringa (Moringa oleifera) is a high-productivity, fast-growing multipurpose plant adapted to dry tropical conditions. In Europe it is susceptible to grow in temperate Mediterranean areas with few frosts. As biomass, the composition of its nutrients makes it very interesting for its consumption, in green or dry, by both animals and people. Its fruits are triangular pods that provide oilseeds, with more than 30% of edible oil in its composition. Moringa pod husk are considered as a waste that, being rich in cellulose, is a source of raw material for the production of bioethanol. The management of the moringa tree crown, necessary for a good and easy harvest, provides a little lignified wood susceptible of being transformed in this biofuel. The massive production of moringa oil in tropical areas can represent an opportunity to value these residues and, with them, help combat the so-called Climatic Change together with the change of land uses and the reforestation of lands currently dedicated to extensive livestock. To explore the feasibility of using these residues for biofuels production, it´s necessary to know: the potential production of the residues obtained in a crop of moringa oil , the results of compositional analysis of stems and pods of moringa and the results obtained in the production of bioalcohol.

Recent Publications:

1. Ali, E. N., & MZ, J. (2015). Possibility of Producing Ethanol from Moringa Oleifera Pod Husk. Journal of Advanced Research Design, 5(1), 1-9.

2. Ali, Eman N. and Umarul, I. A. (2015) Possibility of Producing bioethanol from Moringa oleifera Press Cake. In: Proceedings of The Energy & Materials Research Conference (EMR2015): "Materials and Technologies for Energy Efficiency", 25-27 February 2015 , Madrid, Spain. pp. 22-25.

3. AZIZ, N. M. S. B. A. (2013). Investigating the potential of using Moringa oleifera husks for bioethanol production (Doctoral dissertation, Universiti Malaysia Pahang).

4. Godino García, M.; Izquierdo Osado, M. I. y Arias Sabín, C. (2014). Zonificación bioclimática de la moringa (Moringa oleífera Lam.) en la Península Ibérica para producir biocombustibles. In: Prodeedings of International Congress on Water, Waste and Energy Management Porto July 2014, 16/07/2014 - 18/07/2014, Porto (Portugal). ISBN 978-989-95089-6-5. p. 245

5. Godino García, M.; Izquierdo Osado, M. I. y Villegas, S. (2017). Evaluación del uso energético de la madera de Moringa oleifera. Presented in: 7º Congreso Forestal Español. Gestión del monte Servicios Ambienbtales y Bioeconomía. Plasencia, Cáceres, España. 26/07/2017-30/07/2017, Plasencia (Spain).

6. Martínez Salcedo, P., González, F., Suárez, C.A.,. Escobar, M. (2014). Adaptación y producción de biomasa de moringa (Moringa oleifera Lam.) en tres localidades del Departamento de Santander. Ponencia 6º Simposio Nacional Forestal. Colombia Forestal Vol. 17 (Supl. 1) / Octubre 9-10, 2014

7. Montaño Morales, Héctor Fabio (2014) Producción de bioetanol a partir de material lignocelulósico de moringa oleífera. Maestría thesis, Universidad Nacional de Colombia. http://dx.doi.org/10.1080/15435075.2017.1313738

Shalini Gautam

Indian Institute of Technology (Indian School of Mines), India

Title: Impact of pyrolysis temperature on the characteristics and utilization potential of bio-chars derived from wooden dust

Time : 14:30-15:00

Biography:

Shalini Gautam has more than 15 years of experience in Research & Teaching. She has her expertise in Fuel Technology, Coal characterization, Coal carbonization, Coal combustion and Gasification. Her recent area of work is on ‘Utilization potential of Indian Biomass for different thermo chemical processes like combustion, carbonization, gasification, etc.; utilization of poor quality coking coals for metallurgical applications.

Abstract:

To meet the global demand of energy, coal is the predominant source, which is depleting gradually and requires an alternative source preferably with less concern of climate change. Keeping this in view impact of pyrolysis temperatures on the characteristics of bio-chars derived from pyrolysis of the wooden dust and its utilization potential, was examined. The pyrolysis was carried out in a pyrolysis chamber at 400, 600, 800 and 1000°C for an hour, using heating @ 5-15oC/min. The obtained results evince that wooden dust can be a potential source for pyrolysis. Low temperature pyrolysis produced bio-char with high yield, but high temperature pyrolysis led to low yield bio-char with higher content of carbon and heating values. Thermal analysis of the wooden dust showed higher degradation profile that is weight loss increases with increase in temperature. Bio-chars from wooden dust particularly at temp 600-800oC can be more suitable for steelmaking, in view of their chemical and thermo-chemical characteristics including low ash, higher heating values (HHV), high surface area, etc.. In traditional iron making reduction of iron ores to metallic iron is done by coke which acts as a reductant and source of energy as well. The coal used for coke making is premium in quality and has limited reserves, so an attempt has also been made to reduce the requirements of coking coal using wooden dust char through direct reduction of iron ore.The obtained results show that highest percentage of reduction can be achieved in case of wooden dust char as compared with coal. Also kinetic study of the work shows activation energy 75.16 KJ/mole.

Recent Publications:

1. E. Mousa, C.Wang, J.Riesbeck, M. Larsson: Biomass applications in iron and steel industry:An overview of challenges and opportunities. Renewable and Sustainable Energy Reviews 2016; 65:1247–1266.

2. E. N.Yargicoglu, B. Y.Sadasivam, K. R.ReddyandK.Spokas: Physical and chemicalcharacterization of waste wood derived biochars,Waste Management,2014,36, 256-268.

3. Y. Lee, J. Park, C. Ryu, K. S. Gang, W. Yang, Y. K. Park, J. Jung and S. Hyun: Comparisonof biochar properties from biomass residues produced by slow pyrolysis at 500oC. Bioreso. Techno., 2013, 148,196–201.

4. Pallavi HV, Swamy SS, Kiran BM, Vyshnavi DR, Ashwin CA. BriquettingAgriculturalWastes as an Energy source,J.ofEngg. Sc., Comp. Sc. and Engg. &Tech. 2014; 2:160-172.

5. S. Sengupta: ‘Raw material for steel industry’, Steel World, 2015, 42–52.

Joana Pinto

Universidade Federal do Rio de Janeiro, Brazil

Title: Making a bridge between biomass and hydrocarbon in a standard refinery

Time : 15:00-15:25

Biography:

Joana Pinto is an PhD Student in Federal University of Rio de Janeiro. Joana Pinto research interest is biomass conversion process in order to Making a bridge between biomass and hydrocarbon in a standard refinery.

Abstract:

A conventional refinery is based on mature processes that obtain standard products from a large variety of non- renewable feeds. Despite enormous benefits to modern civilization, the adopted production and consumption patterns paradoxically put us at environmental risk. Therefore it is mandatory a paradigm shift to decrease the carbon footprint without reducing the energy access to people. Biomass is composed of functionalized biopolymers (lignin-cellulose) based on sugars- and phenol-derivatives. On the other hand, refinery processes have been designed to operate on poorly reactive compounds like hydrocarbons. The bridge between these two remarkable worlds was archived in two steps: 1- by transforming the biomass into a bio-crude, which was produced by ketalyzation in acetone [1, 2] and acetylation reactions in acetic anhydride [3] under mild temperature conditions (around 100oC). This black bio-crude (density around 1.0-1.3 gmL-1 and CHO composition of 60, 8 and 32 respectively) is chemically distinct of any other bio-feed so far. 2 -The transformation of bio-crude and model compounds by the fluid catalytic cracking and hydrotreatment into monoaromatic and saturated hydrocarbons respectively [4]. Herein the results of the fluidized bed pilot plant in laboratory scale of both model test and bio-crude are presented. For instance, a representative ketal-derivative, 1,2:5,6-di-O- isopropylidene-α-D-glucofuranose (DX) mixture up to 50% in n-hexane achieved three main goals: small coke formation, remarkable selectivity to hydrocarbons and slight improvement in n-hexane conversion as presented in Table 1. Moreover, no oxygenated compounds were observed in the liquid phase, thus resulting in a drop-in fraction in the fuel pool.

Table 1: FCC test with a feed of 30 wt.% of DX in n- hexane cracking and pristine n-hexane in the presence of 20 g of a commercial FCC catalyst, 10 mL min temperature 420-500oC. All data in %

|

|

Coke cat. |

Yield |

Sel. Ar. |

n-C6 conv. |

||

|

Gas |

Liquid |

Coke |

||||

|

n-C6 |

4.8 |

20 |

68 |

16 |

13 |

10 11 |

|

30% DX |

6.4 |

22 |

66 |

19 |

52 |

|

The bio-base economy derived from this concept fits the requirements to be produced, transported and processed like wise to the up- to downstream in the oil industry. Finally, as a consequence the bio-crude behaves like hydrocarbons under realistic refinery process, oil could be partially substituted by bio-crude or, in the future; an entirely green refinery could operate using renewable feeds.

Recent Publications

[1] N. Batalha, A.V.d. Silva, M.O.d. Souza, B.M.C.d. Costa, E.S. Gomes, T.C. Silva, T.G. Barros, M.L.A. Gonçalves, E.B. Caramão, L.R.M.d. Santos, M.B.B.

Almeida, R.O.M.A.d. Souza, Y.L. Lam, N.M.F. Carvalho,

L.S.M. Miranda, M.M. Pereira, Gasoline from Biomass through Refinery-Friendly Carbohydrate-Based Bio-Oil Produced by Ketalization, CHEMSUSCHEM, 7 (2014) 1627–1636.

[2] R. Garrett, T.G. Barros, M.O. de Souza, B.M.C. da Costa, M.M. Pereira, L.S.M. Miranda, Unveiling the chemical composition of sugar cane biocrudes by liquid chromatography-tandem mass spectrometry, Energy & Fuels, 29 (2015) 8082-8087.

[3] J.A.C. Durange, M.O. de Souza, M.R.L. Santos, M. Nele, E.B. Caramão, N.M.F. Carvalho, M.M. Pereira, Valorization of Sugar Cane Bagasse and Jatropha Curcas Cake: Production of a Biocrude by Acetylation Reaction under Microwave Radiation, Energy & Fuels, 29 (2015) 917–921.

[4] N. Batalha, J. Pinto, H. Ferreira, D.C. Baptista, L.S.M. Miranda, M.M. Pereira, Biohydrocarbons Production under Standard Refinery Conditions by means of a Representative Ketal Compound of Biocrude, Energy Technology, (2016) DOI: 10.1002/ente.201600313.

Break:

Networking and Refreshments Break 15:25-15:45 @ Breakout Area