Shalini Gautam

Indian Institute of Technology (Indian School of Mines), India

Title: Impact of pyrolysis temperature on the characteristics and utilization potential of bio-chars derived from wooden dust

Biography

Biography: Shalini Gautam

Abstract

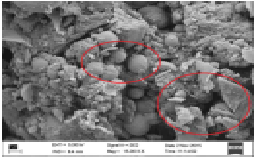

To meet the global demand of energy, coal is the predominant source, which is depleting gradually and requires an alternative source preferably with less concern of climate change. Keeping this in view impact of pyrolysis temperatures on the characteristics of bio-chars derived from pyrolysis of the wooden dust and its utilization potential, was examined. The pyrolysis was carried out in a pyrolysis chamber at 400, 600, 800 and 1000°C for an hour, using heating @ 5-15oC/min. The obtained results evince that wooden dust can be a potential source for pyrolysis. Low temperature pyrolysis produced bio-char with high yield, but high temperature pyrolysis led to low yield bio-char with higher content of carbon and heating values. Thermal analysis of the wooden dust showed higher degradation profile that is weight loss increases with increase in temperature. Bio-chars from wooden dust particularly at temp 600-800oC can be more suitable for steelmaking, in view of their chemical and thermo-chemical characteristics including low ash, higher heating values (HHV), high surface area, etc.. In traditional iron making reduction of iron ores to metallic iron is done by coke which acts as a reductant and source of energy as well. The coal used for coke making is premium in quality and has limited reserves, so an attempt has also been made to reduce the requirements of coking coal using wooden dust char through direct reduction of iron ore.The obtained results show that highest percentage of reduction can be achieved in case of wooden dust char as compared with coal. Also kinetic study of the work shows activation energy 75.16 KJ/mole.

Recent Publications:

1. E. Mousa, C.Wang, J.Riesbeck, M. Larsson: Biomass applications in iron and steel industry:An overview of challenges and opportunities. Renewable and Sustainable Energy Reviews 2016; 65:1247–1266.

2. E. N.Yargicoglu, B. Y.Sadasivam, K. R.ReddyandK.Spokas: Physical and chemicalcharacterization of waste wood derived biochars,Waste Management,2014,36, 256-268.

3. Y. Lee, J. Park, C. Ryu, K. S. Gang, W. Yang, Y. K. Park, J. Jung and S. Hyun: Comparisonof biochar properties from biomass residues produced by slow pyrolysis at 500oC. Bioreso. Techno., 2013, 148,196–201.

4. Pallavi HV, Swamy SS, Kiran BM, Vyshnavi DR, Ashwin CA. BriquettingAgriculturalWastes as an Energy source,J.ofEngg. Sc., Comp. Sc. and Engg. &Tech. 2014; 2:160-172.

5. S. Sengupta: ‘Raw material for steel industry’, Steel World, 2015, 42–52.