Day 2 :

Keynote Forum

Vance N. Owens

South Dakota State University, USA

Keynote: Potential yield of dedicated energy crops: results and outcomes of the sun grant regional feedstock partnership

Time : 10:10-10:45

Biography:

Vance Owens received BS, MS, and PhD degrees at Brigham Young University, Utah State University, and the University of Wisconsin-Madison, respectively. He is Director of the North Central Sun Grant Center and Professor of Plant Science at South Dakota State University. He has conducted research on production of bioenergy feedstock crops, specifically perennial species, for more than 20 years.

Abstract:

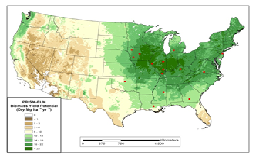

Statement of the Problem: The Sun Grant Regional Feedstock Partnership commenced in 2007 with the goal of supporting the realization of the biomass potential envisioned in DOE’s 2005 Billion Ton Report. Concluding in 2016, the partnership sought to increase the knowledge of bioenergy through coordinated feedstock research across the lower 48 states and Hawaii with partners in academia, government, and private industry. Methodology & Theoretical Orientation: The core of the research includes over 130 field trials and regional resource assessment activities focused on agricultural residues and a suite of likely dedicated energy crops. In 2013 a series of meetings was held across the US with each of the crop teams and the resource assessment team, led by the Oregon State University and Oak Ridge National Laboratory, to review, standardize, and verify yield trial data and assimilate their outcomes into a national model of biomass yield suitability. The meetings provided a way to “ground truth” yield estimates in order to accurately capture interactions of climate and soils for dedicated energy crops, including switchgrass, energycane, biomass sorghum, CRP mixtures, Miscanthus x giganteus, hybrid poplar, and willow. Findings: From these sets of funded trials and historical data, yield was estimated across spatial gradients according to soil characteristics and climate history (see Figure 1 for Giant Miscanthus example). The resulting spatial grids provide critical information for policymakers and planners of the potential productivity of these pre-commercial crops. National yield estimates, as well as overall yield across the continental USA, demonstrated potential for these diverse feedstock resources. Conclusion & Significance: Production and management data, as well as biomass composition characteristics, provide empirical support of logistic design and feedstock supply systems. These data and maps are vital for policy makers, producers, end-users, and others in the bioeconomy.

Recent Publications

1. D.K. Lee, 55 other authors, and V. Owens. 2017. Biomass Production of Herbaceous Energy Crops in the United States: Field Trial Results and Yield Potential Maps from the Multiyear Regional Feedstock Partnership. GCB Bioenergy (Accepted).

2. Liming Lai, Chang Oh Hong, Sandeep Kumar, Shannon L. Osborne, R. Michael Lehman and Vance N. Owens. 2017. Soil nitrogen dynamics in switchgrass seeded to a marginal cropland in South Dakota. GCB Bioenergy, doi:10.1111/gcbb.12475.

3. John H. Fike, James W. Pease, Vance N. Owens, Rodney L. Farris, Julie L. Hansen, Emily A. Heaton, Chang O. Hong, Hilary S. Mayton, Robert B . Mitchell and Donald R. Viands. 2017. Switchgrass nitrogen response and estimated production costs on diverse sites. GCB Bioenergy (2017), doi: 10.1111/gcbb.12444.

4. Arvid Boe, Paul J. Johnson, Vance Owens, DoKyoung Lee, Jia Guo, Jose L. Gonzalez- Hernandez. 2017. Genetics and Partitioning for Biomass of Prairie Cordgrass Compared to Switchgrass on Marginal Cropland. Bioenergy Research DOI 10.1007/s12155-017-9849-0.

5. Ibrahim, M., Chang Oh. Hong, S. Singh, S. Kumar, S. Osborne, and V. Owens. 2017. Switchgrass biomass quality as affected by nitrogen rates, harvest time, and storage. Agron. J. 109:1–11, doi:10.2134/agronj2016.07.0380.

6. Owens, V.N., D.R. Viands, H.S. Mayton, J.H. Fike, R. Farris, E. Heaton, D.I. Bransby, C.O. Hong. 2013. Nitrogen use in switchgrass grown for bioenergy across the USA. Biomass and Bioenergy http://dx.doi.org/10.1016/j.biombioe.2013.07.016.

Break:

Networking and Refreshments Break 10:45-11:05 @ Breakout Areas

Keynote Forum

Matjaz Kunaver

National Institute of Chemistry, Slovenia

Keynote: Biomass waste – A source of raw materials and nanocellulose

Time : 11:05-11:40

Biography:

Abstract:

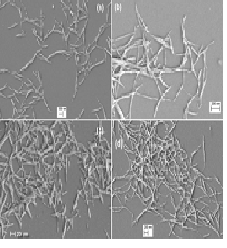

Cellulose containing Biomass represents an immense and renewable source for the production of bio-fuels and valuable chemicals. A little amount of this is used in industry and the remaining is leftover in huge quantities. Much effort has been devoted in converting these types of biomass into useful industrial and commercially viable products. In recent years, some effective processes have been found, such as thermochemical conversion producing several new products from these renewable resources. An overview of such applications and methods will be presented in this contribution. One of possibilities of converting biomass is the liquefaction. During liquefaction reaction, lignocellulosic components are depolymerized to low molecular mass compounds with high reactivity, high hydroxyl group content and can be used in many useful applications. A high energy ultrasound or microwaves can be used as an energy source to speed up the liquefaction process. The liquefied biomass was used as a feedstock in the synthesis of polyesters, polyurethane foams and adhesives. The same liquefaction process was used for the isolation of the nanocrystalline cellulose from biomass. The method is a novelty and a model procedure for NCC isolation from different natural cellulosic sources with high yields and with high crystallinity index. The process of

Cellulose containing Biomass represents an immense and renewable source for the production of bio-fuels and valuable chemicals. A little amount of this is used in industry and the remaining is leftover in huge quantities. Much effort has been devoted in converting these types of biomass into useful industrial and commercially viable products. In recent years, some effective processes have been found, such as thermochemical conversion producing several new products from these renewable resources. An overview of such applications and methods will be presented in this contribution. One of possibilities of converting biomass is the liquefaction. During liquefaction reaction, lignocellulosic components are depolymerized to low molecular mass compounds with high reactivity, high hydroxyl group content and can be used in many useful applications. A high energy ultrasound or microwaves can be used as an energy source to speed up the liquefaction process. The liquefied biomass was used as a feedstock in the synthesis of polyesters, polyurethane foams and adhesives. The same liquefaction process was used for the isolation of the nanocrystalline cellulose from biomass. The method is a novelty and a model procedure for NCC isolation from different natural cellulosic sources with high yields and with high crystallinity index. The process of

[1] Kunaver M, JasiukaitytÄ— E, ÄŒuk N (2012) Ultrasonically assisted liquefaction of lignocellulosic materials Bioresource Technology 103:360-366

[2] Kunaver M, Anžlovar A, Žagar E (2016) The fast and effective isolation of nanocellulose from selected cellulosic feedstocks Carbohydrate polymers 148:251-256

[3] Khalil H P S A, Bhat A H, Yusra A F I (2012) green composites from sustainable cellulose nanofibrils: a review Carbohydrate Polymers 87: 963-979

[4] Fan J, Li Y Maximazing the yield of nanocrystalline cellulose from cotton pulp fiber (2012) Carbohydrate Polymer 88:1184-1188

[5] Texeira et al. (2010) Cellulose nanofibers from white and naturally colored cotton fibers Cellulose 17: 595-606

Keynote Forum

Paul R James

Ramboll, United Kingdom

Keynote: GHG reduction options for coal fired power stations

Time : 11:40-12:15

Biography:

Paul R James is trained as a Chemist and in Chemical Engineering, Paul has spent some 25 years working in the Energy and Environment fields in both the Public and Private Sector.

His early career included managing Environment & Energy performance in the Pharmaceutical Sector, policy development and regulation of major industry in the UK and Europe, and latterly consulting on large scale energy and waste projects. He the Chairman of the UK Chartered Institute of Wastes Management (CIWM) Special Interest Group on Thermal Waste Treatment.

Abstract:

The presentation will provide an overview of developments in the energy supply market that are resulting in increased biomass co-firing and conversion of existing coal fired assets to use biomass. It will explain the policy and market conditions, as well as the technical adaptations, challenges and benefits associated with reducing GHG emissions using biomass, including several possible ways of significantly reducing the GHG foot print of a coal fired power station based on experienced and proven technological solutions from bioconversion projects executed over the last 20 years in Denmark. The presentation will present options based on two case studies, comprising the successful conversion of existing plants in the range from 100 MWe up to 500 MWe to biomass firing. The systems to be explained will briefly include fuel handling and preparation, combustion systems and boilers and display the differences between the options in capital expenditure and reduction in GHG emissions.

- Biomass Energy Resources | Pyrolysis | Renewable Energy

Location: Johnson

Chair

Robert Helleur

Memorial University of Newfoundland, Canada

Co-Chair

Marcelo Maciel Pereira

Universidade Federal do Rio de Janeiro, Brazil

Session Introduction

Tony Tiyou

Renewables in Africa, UK

Title: Bioenergy industry prospects in Africa

Time : 12:15-12:45

Biography:

Tony Tiyou holds a triple Engineering Master’s Degree from Cranfield University (UK), Ecole Centrale de Lille (France) and Faculte Polytechnique de Mons (Belgium). Tony also holds qualifications as Renewable Energy expert from the European Energy Centre (UK). After having worked and held various positions and roles for about a decade in both the Automotive and the Renewable Industry, Tony has founded with a partner, a consultancy, O’wango & TT Smart (O&TT). In September 2016, he launched a blog: Renewables in Africa.

Abstract:

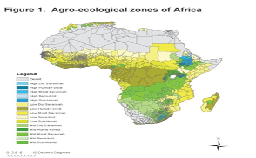

Background: Africa is endowed with vast renewable energy resources that can provide solutions to the severe energy issues the continent is experiencing. Among them, hydropower stands as the cheapest of all and has historically being the most exploited. Since the last decade, the continent is increasingly turning to solar PV and wind to bolster energy security and support rapid economic growth in a sustainable manner. This has been due in large part to improving technology and declining costs of equipment. In comparison, bioenergy which is currently widely used for cooking and heating is almost untapped as far as power generation is concerned.

Resources: At the difference of widespread solar, bioenergy is only present in large quantities in specific areas where rain is abundant, like Central Africa and parts of West and East Africa. Although less well-off, North Africa and Southern Africa are nevertheless looking as well at harnessing this energy to enhance the diversification of their energy mix. Across Africa, the technical potential for the use of bioenergy for power generation is estimated at 2.631 TWh, with 60% in Central Africa. Bioenergy is usually being exploited in one of its three forms: solid biomass, biogas and biofuels.

Market Opportunities: The current market in Africa is still in burgeoning stages. Investments and technologies have essentially been the main obstacles. Kenya has been experimenting biogas for few decades. Although they have been unlucky so far, they are still pursuing their development. Other countries like Senegal, Burkina Faso, Mauritania and Ethiopia have also express interest into the industry. Estimates suggest that South Africa could generate 5% of its electricity from biogas. Should it be exploited through the REIPPP, this will have the potential to transform the whole industry on the continent, like it has been the case for solar and wind.

Recent Publications

1. IRENA, Prospects for the African Power Sector

2. IRENA, AFRICA POWER SECTOR: Planning and Prospects for Renewable Energy

3. IRENA, Estimating the Renewable Energy Potential in Africa

4. IRENA, Biomass Potential in Africa

5. AFREA (Wold Bank), Wood-Based Biomass Energy Development for Sub-Saharan Africa

6. Klas Sander, Wood-Based Biomass Energy in Sub-Saharan Africa: Issues & Approaches

7. Belynda Petrie, South Africa A case for biomass?

8. Belynda Petrie and Duncan Macqueen, South African biomass energy: little heeded but much needed

9. http://www.ipsnews.net/2016/05/biomass-could-help-power-africas-energy- transition

10. http://www.wur.nl/en/show/Opportuniti es-Map-predicting-possible-crop- production-1.htm?wmstepid=mail_de_auteur

Marcelo Maciel Pereira

Universidade Federal do Rio de Janeiro, Brazil

Title: Making a bridge between biomass and hydrocarbon in a standard refinery

Time : 12:45-13:15

Biography:

Marcelo Maciel Pereira is an Associate Professor at the Chemistry Institute of Federal University of Rio de Janeiro (UFRJ - Brazil). He obtained the MSc and the Ph.D. in Chemical Engineering at Federal University of Rio de Janeiro. His research interests focus on kinetics and catalysis, hydrocarbons, biomass conversion, zeolites, CO2, greenhouse gas emissions and sequestration.

Abstract:

A conventional refinery is based on mature processes that obtain standard products from a large variety of non- renewable feeds. Despite enormous benefits to modern civilization,3 the adopted production and consumption patterns paradoxically put us at environmental risk. Therefore it is mandatory a paradigm shift to decrease the carbon footprint without reducing the energy access to people. Biomass is composed of functionalized biopolymers (lignin-cellulose) based on sugars- and phenol-derivatives. On the other hand, refinery processes have been designed to operate on poorly reactive compounds like hydrocarbons. The bridge between these two remarkable worlds was archived in two steps: 1- by transforming the biomass into a bio-crude, which was produced by ketalyzation in acetone [1, 2] and acetylation reactions in acetic anhydride [3] under mild temperature conditions (around 100oC). This black bio-crude (density around 1.0-1.3 gmL-1 and CHO composition of 60, 8 and 32 respectively) is chemically distinct of any other bio-feed so far. 2 -The transformation of bio-crude and model compounds by the fluid catalytic cracking and hydrotreatment into monoaromatic and saturated hydrocarbons respectively [4]. Herein the results of the fluidized bed pilot plant in laboratory scale of both model test and bio-crude are presented. For instance, a representative ketal-derivative, 1,2:5,6-di-O- isopropylidene-α-D-glucofuranose (DX) mixture up to 50% in n-hexane achieved three main goals: small coke formation, remarkable selectivity to hydrocarbons and slight improvement in n-hexane conversion as presented in Table 1. Moreover, no oxygenated compounds were observed in the liquid phase, thus resulting in a drop-in fraction in the fuel pool. The bio-base economy derived from this concept fits the requirements to be produced, transported and processed like wise to the up- to downstream in the oil industry. Finally, as a consequence the bio-crude behaves like hydrocarbons under realistic refinery process, oil could be partially substituted by bio-crude or, in the future; an entirely green refinery could operate using renewable feeds.

|

|

Coke cat. |

Yield |

Sel. Ar. |

n-C6 conv. |

||

|

Gas |

Liquid |

Coke |

||||

|

n-C6 |

4.8 |

20 |

68 |

16 |

13 |

|

|

30% DX |

6.4 |

22 |

66 |

19 |

50 |

|

Recent Publications

[1] N. Batalha, A.V.d. Silva, M.O.d. Souza, B.M.C.d. Costa, E.S. Gomes, T.C. Silva, T.G. Barros, M.L.A. Gonçalves, E.B. Caramão, L.R.M.d. Santos, M.B.B. Almeida, R.O.M.A.d. Souza, Y.L. Lam, N.M.F. Carvalho, L.S.M. Miranda, M.M. Pereira, Gasoline from Biomass through Refinery-Friendly Carbohydrate-Based Bio-Oil Produced by Ketalization, CHEMSUSCHEM, 7 (2014) 1627–1636.

[2] R. Garrett, T.G. Barros, M.O. de Souza, B.M.C. da Costa, M.M. Pereira, L.S.M. Miranda, Unveiling the chemical composition of sugar cane biocrudes by liquid chromatography-tandem mass spectrometry, Energy & Fuels, 29 (2015) 8082-8087.

[3] J.A.C. Durange, M.O. de Souza, M.R.L. Santos, M. Nele, E.B. Caramão, N.M.F. Carvalho, M.M. Pereira, Valorization of Sugar Cane Bagasse and Jatropha Curcas Cake: Production of a Biocrude by Acetylation Reaction under Microwave Radiation, Energy & Fuels, 29 (2015) 917–921.

[4] N. Batalha, J. Pinto, H. Ferreira, D.C. Baptista, L.S.M. Miranda, M.M. Pereira, Biohydrocarbons Production under Standard Refinery Conditions by means of a Representative Ketal Compound of Biocrude, Energy Technology, (2016) DOI: 10.1002/ente.201600313.

Lunch Break 13:15-14:00 @ RBG

Miguel Godino Garcia

UPM, Spain

Title: Moringa oleifera crop residues as a source of bioethanol

Time : 14:00-14:30

Biography:

Miguel Godino García is a professor at the School of Forestry Engineers of the Universidad Politécnica de Madrid. He has been involved in cooperation projects in Colombia for 8 years, promoting the integral development of moringa cultivation and its different uses, focusing on the production of moringa oil. In collaboration with the University of Tolima, it is being promoted the creation of a university network with different Colombian universities opened to other universities.

Abstract:

Moringa (Moringa oleifera) is a high-productivity, fast-growing multipurpose plant adapted to dry tropical conditions. In Europe it is susceptible to grow in temperate Mediterranean areas with few frosts. As biomass, the composition of its nutrients makes it very interesting for its consumption, in green or dry, by both animals and people. Its fruits are triangular pods that provide oilseeds, with more than 30% of edible oil in its composition. Moringa pod husk are considered as a waste that, being rich in cellulose, is a source of raw material for the production of bioethanol. The management of the moringa tree crown, necessary for a good and easy harvest, provides a little lignified wood susceptible of being transformed in this biofuel. The massive production of moringa oil in tropical areas can represent an opportunity to value these residues and, with them, help combat the so-called Climatic Change together with the change of land uses and the reforestation of lands currently dedicated to extensive livestock. To explore the feasibility of using these residues for biofuels production, it´s necessary to know: the potential production of the residues obtained in a crop of moringa oil , the results of compositional analysis of stems and pods of moringa and the results obtained in the production of bioalcohol.

Recent Publications:

1. Ali, E. N., & MZ, J. (2015). Possibility of Producing Ethanol from Moringa Oleifera Pod Husk. Journal of Advanced Research Design, 5(1), 1-9.

2. Ali, Eman N. and Umarul, I. A. (2015) Possibility of Producing bioethanol from Moringa oleifera Press Cake. In: Proceedings of The Energy & Materials Research Conference (EMR2015): "Materials and Technologies for Energy Efficiency", 25-27 February 2015 , Madrid, Spain. pp. 22-25.

3. AZIZ, N. M. S. B. A. (2013). Investigating the potential of using Moringa oleifera husks for bioethanol production (Doctoral dissertation, Universiti Malaysia Pahang).

4. Godino García, M.; Izquierdo Osado, M. I. y Arias Sabín, C. (2014). Zonificación bioclimática de la moringa (Moringa oleífera Lam.) en la Península Ibérica para producir biocombustibles. In: Prodeedings of International Congress on Water, Waste and Energy Management Porto July 2014, 16/07/2014 - 18/07/2014, Porto (Portugal). ISBN 978-989-95089-6-5. p. 245

5. Godino García, M.; Izquierdo Osado, M. I. y Villegas, S. (2017). Evaluación del uso energético de la madera de Moringa oleifera. Presented in: 7º Congreso Forestal Español. Gestión del monte Servicios Ambienbtales y Bioeconomía. Plasencia, Cáceres, España. 26/07/2017-30/07/2017, Plasencia (Spain).

6. Martínez Salcedo, P., González, F., Suárez, C.A.,. Escobar, M. (2014). Adaptación y producción de biomasa de moringa (Moringa oleifera Lam.) en tres localidades del Departamento de Santander. Ponencia 6º Simposio Nacional Forestal. Colombia Forestal Vol. 17 (Supl. 1) / Octubre 9-10, 2014

7. Montaño Morales, Héctor Fabio (2014) Producción de bioetanol a partir de material lignocelulósico de moringa oleífera. Maestría thesis, Universidad Nacional de Colombia. http://dx.doi.org/10.1080/15435075.2017.1313738

Shalini Gautam

Indian Institute of Technology (Indian School of Mines), India

Title: Impact of pyrolysis temperature on the characteristics and utilization potential of bio-chars derived from wooden dust

Time : 14:30-15:00

Biography:

Shalini Gautam has more than 15 years of experience in Research & Teaching. She has her expertise in Fuel Technology, Coal characterization, Coal carbonization, Coal combustion and Gasification. Her recent area of work is on ‘Utilization potential of Indian Biomass for different thermo chemical processes like combustion, carbonization, gasification, etc.; utilization of poor quality coking coals for metallurgical applications.

Abstract:

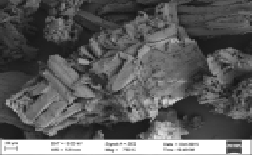

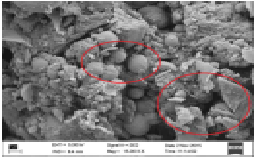

To meet the global demand of energy, coal is the predominant source, which is depleting gradually and requires an alternative source preferably with less concern of climate change. Keeping this in view impact of pyrolysis temperatures on the characteristics of bio-chars derived from pyrolysis of the wooden dust and its utilization potential, was examined. The pyrolysis was carried out in a pyrolysis chamber at 400, 600, 800 and 1000°C for an hour, using heating @ 5-15oC/min. The obtained results evince that wooden dust can be a potential source for pyrolysis. Low temperature pyrolysis produced bio-char with high yield, but high temperature pyrolysis led to low yield bio-char with higher content of carbon and heating values. Thermal analysis of the wooden dust showed higher degradation profile that is weight loss increases with increase in temperature. Bio-chars from wooden dust particularly at temp 600-800oC can be more suitable for steelmaking, in view of their chemical and thermo-chemical characteristics including low ash, higher heating values (HHV), high surface area, etc.. In traditional iron making reduction of iron ores to metallic iron is done by coke which acts as a reductant and source of energy as well. The coal used for coke making is premium in quality and has limited reserves, so an attempt has also been made to reduce the requirements of coking coal using wooden dust char through direct reduction of iron ore.The obtained results show that highest percentage of reduction can be achieved in case of wooden dust char as compared with coal. Also kinetic study of the work shows activation energy 75.16 KJ/mole.

Recent Publications:

1. E. Mousa, C.Wang, J.Riesbeck, M. Larsson: Biomass applications in iron and steel industry:An overview of challenges and opportunities. Renewable and Sustainable Energy Reviews 2016; 65:1247–1266.

2. E. N.Yargicoglu, B. Y.Sadasivam, K. R.ReddyandK.Spokas: Physical and chemicalcharacterization of waste wood derived biochars,Waste Management,2014,36, 256-268.

3. Y. Lee, J. Park, C. Ryu, K. S. Gang, W. Yang, Y. K. Park, J. Jung and S. Hyun: Comparisonof biochar properties from biomass residues produced by slow pyrolysis at 500oC. Bioreso. Techno., 2013, 148,196–201.

4. Pallavi HV, Swamy SS, Kiran BM, Vyshnavi DR, Ashwin CA. BriquettingAgriculturalWastes as an Energy source,J.ofEngg. Sc., Comp. Sc. and Engg. &Tech. 2014; 2:160-172.

5. S. Sengupta: ‘Raw material for steel industry’, Steel World, 2015, 42–52.

Joana Pinto

Universidade Federal do Rio de Janeiro, Brazil

Title: Making a bridge between biomass and hydrocarbon in a standard refinery

Time : 15:00-15:25

Biography:

Joana Pinto is an PhD Student in Federal University of Rio de Janeiro. Joana Pinto research interest is biomass conversion process in order to Making a bridge between biomass and hydrocarbon in a standard refinery.

Abstract:

A conventional refinery is based on mature processes that obtain standard products from a large variety of non- renewable feeds. Despite enormous benefits to modern civilization, the adopted production and consumption patterns paradoxically put us at environmental risk. Therefore it is mandatory a paradigm shift to decrease the carbon footprint without reducing the energy access to people. Biomass is composed of functionalized biopolymers (lignin-cellulose) based on sugars- and phenol-derivatives. On the other hand, refinery processes have been designed to operate on poorly reactive compounds like hydrocarbons. The bridge between these two remarkable worlds was archived in two steps: 1- by transforming the biomass into a bio-crude, which was produced by ketalyzation in acetone [1, 2] and acetylation reactions in acetic anhydride [3] under mild temperature conditions (around 100oC). This black bio-crude (density around 1.0-1.3 gmL-1 and CHO composition of 60, 8 and 32 respectively) is chemically distinct of any other bio-feed so far. 2 -The transformation of bio-crude and model compounds by the fluid catalytic cracking and hydrotreatment into monoaromatic and saturated hydrocarbons respectively [4]. Herein the results of the fluidized bed pilot plant in laboratory scale of both model test and bio-crude are presented. For instance, a representative ketal-derivative, 1,2:5,6-di-O- isopropylidene-α-D-glucofuranose (DX) mixture up to 50% in n-hexane achieved three main goals: small coke formation, remarkable selectivity to hydrocarbons and slight improvement in n-hexane conversion as presented in Table 1. Moreover, no oxygenated compounds were observed in the liquid phase, thus resulting in a drop-in fraction in the fuel pool.

Table 1: FCC test with a feed of 30 wt.% of DX in n- hexane cracking and pristine n-hexane in the presence of 20 g of a commercial FCC catalyst, 10 mL min temperature 420-500oC. All data in %

|

|

Coke cat. |

Yield |

Sel. Ar. |

n-C6 conv. |

||

|

Gas |

Liquid |

Coke |

||||

|

n-C6 |

4.8 |

20 |

68 |

16 |

13 |

10 11 |

|

30% DX |

6.4 |

22 |

66 |

19 |

52 |

|

The bio-base economy derived from this concept fits the requirements to be produced, transported and processed like wise to the up- to downstream in the oil industry. Finally, as a consequence the bio-crude behaves like hydrocarbons under realistic refinery process, oil could be partially substituted by bio-crude or, in the future; an entirely green refinery could operate using renewable feeds.

Recent Publications

[1] N. Batalha, A.V.d. Silva, M.O.d. Souza, B.M.C.d. Costa, E.S. Gomes, T.C. Silva, T.G. Barros, M.L.A. Gonçalves, E.B. Caramão, L.R.M.d. Santos, M.B.B.

Almeida, R.O.M.A.d. Souza, Y.L. Lam, N.M.F. Carvalho,

L.S.M. Miranda, M.M. Pereira, Gasoline from Biomass through Refinery-Friendly Carbohydrate-Based Bio-Oil Produced by Ketalization, CHEMSUSCHEM, 7 (2014) 1627–1636.

[2] R. Garrett, T.G. Barros, M.O. de Souza, B.M.C. da Costa, M.M. Pereira, L.S.M. Miranda, Unveiling the chemical composition of sugar cane biocrudes by liquid chromatography-tandem mass spectrometry, Energy & Fuels, 29 (2015) 8082-8087.

[3] J.A.C. Durange, M.O. de Souza, M.R.L. Santos, M. Nele, E.B. Caramão, N.M.F. Carvalho, M.M. Pereira, Valorization of Sugar Cane Bagasse and Jatropha Curcas Cake: Production of a Biocrude by Acetylation Reaction under Microwave Radiation, Energy & Fuels, 29 (2015) 917–921.

[4] N. Batalha, J. Pinto, H. Ferreira, D.C. Baptista, L.S.M. Miranda, M.M. Pereira, Biohydrocarbons Production under Standard Refinery Conditions by means of a Representative Ketal Compound of Biocrude, Energy Technology, (2016) DOI: 10.1002/ente.201600313.

Break:

Networking and Refreshments Break 15:25-15:45 @ Breakout Area