Day 1 :

Keynote Forum

Robert Helleur

Memorial University of Newfoundland, Canada

Keynote: An integrated thermochemcial biorefinery for maritime forests

Time : 10:30-11:05

Biography:

Robert Helleur is a Honorary Research Professor of Chemistry at Memorial University. He has been very active in the field of analytical pyrolysis since 1986 in the area of thermochemolytic analysis of chemical markers/ profiling of carbohydrates, lignins, tannins, lipids and plant stressors in biomass and soils. A shift in research focus occurred in 2010 towards applied pyrolysis of forestry residues and municipal wastes with research funds from NSERC, NCE (BioFuelNet), and CFSI/Forestry. Pyrolysis experiments are conducted at lab- and pilot-scale and comprehensive analysis for the biochar and bio-oil products undertaken using various feedstock compositions. Biochars has been used in greenhouse studies for plant growth studies while crude bio-oils have been studied for their chemical stability and extraction of useful chemicals. Dr. Helleur has supervised over 60 graduate students and has published over 75 peer-reviewed research articles. He has been active member in a number of pyrolysis workshops and international conferences.

Abstract:

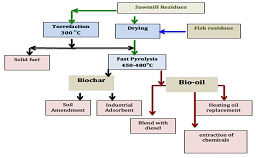

Biorefining is defined as the sustainable processing of biomass into marketable products and fuel. In the Canadian Maritimes waste biomass can be readily obtained from forestry and fishery sectors and municipalities (solid wastes). The integrated forest biorefinery consists of the addition of biorefining units to pulp and paper mills and local sawmills while maintaining the manufacturing of their core product. The biorefinery would provide a source of sustainable fuels and chemicals while increasing the value from wood residues and help diversify the sector. Processing woody biomass into fuels is the first step in biorefining, similar to the atmospheric distillation unit at an oil refinery or inlet separator at a gas plant. Over the last 4 years Memorial has partnered with BioFuelNet Canada, CSFI/DNR and Abritech (Quebec) in developing a comprehensive thermochemical research facility which includes a pilot scale fast pyrolysis unit (450-480oC;no O2). Pyrolysis converts biomass into liquid biofuel, biochar and useful chemical products. Given the average residues of a medium sawmill i.e., 3,500 tonnes/yr and the potential for other feedstocks (fishery) a number of integrated pathways are being considered (Figure 1). The bio-oil has the potential for a replacement or blend with heating oil for the sawmill and region. Depending on scale of the system there are opportunities to partner with other users such as pulp and Paper mills. The biochar product has a number of local markets including soil amendment and as an effective absorbent in the mining and oil and gas industry. Other integrated processes under development are torrefaction (300 oC; no O2), a pre-treatment leading to higher quality products.

Recent Publication:

Papari et al., Indust. Eng. Chem. Res., 56, 2017.

Whyte et al., Fuel processing Tech., 140, 2015.

Kan et al., RSER, 57, 2016.

Ferraro et al., Materials Sci. Eng. C, 33, 2013.

Zhang et al., Energy Conversion Management, 51, 2010.

Break:

Networking and Refreshments Break 11:05-11:25 @ Breakout Areas

Keynote Forum

Hussam Jouhara

Brunel University, London

Keynote: Heat pipe based waste treatment system for biomass production from municipal waste

Time : 11:25-12:00

Biography:

Dr Hussam Jouhara worked in academia and the industry, Hussam has unique expertise in working on applied heat exchangers and energy-related research activities with direct support from research councils and various UK and international industrial partners. He has extensive expertise in designing and manufacturing various types of heat exchangers, including heat pipes and heat pipe-based heat exchangers for low, medium and high temperature applications. His work in the field of heat pipe based heat exchangers resulted in novel designs for recouperators, steam generators & condensers and flat heat pipes. His latest invention relates to a new Waste to Energy system that converts municipal waste to fuel that can be used to heat our homes.

Abstract:

Statement of the Problem: Waste management is one of the most crucial challenges that developed countries are currently facing. The environmental, economic and social effects of current waste treatments prove their inefficiency. Currently, domestic waste must be transported and disposed of in landfills or be burned in mass incinerators. Pyrolysis is a thermal treatment designed to recover energy, which can also contribute to reduce the biodegradable waste volume of landfills.

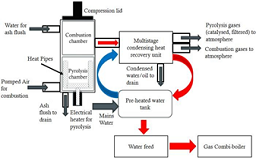

However, current pyrolysis systems cannot cope efficiently enough with the changing heat transfer from the heated walls to the materials and they require the development of very high temperatures on the chamber walls to overcome the thermal resistance within the reactor. Methodology & Theoretical Orientation: An innovative pyrolysis system is introduced. The heat pipe based waste treatment for the Home Energy Recovery Unit (HERU) does not involve any pre-treatment of the waste stream. The HERU achieves high uniformity of the heat distribution within the chamber and high energy recovery. After the waste treatment the waste heat from the pyrolysis process is used to warm up water to cover domestic hot water demands. Findings: The COP of the HERU system can reach up to 9.4, while the carbon footprint of the unit was between 0.0782 to 0.3873 kgCO2e per kg of treated waste. Conclusion & Significance: The HERU provides a green solution to the disposal of waste streams and at the same time a sustainable, renewable solution to power generation. Its implementation could reduce greenhouse gas emissions, diminish the biodegradable content of residual waste sent to landfill, generate fuels and help the government to achieve low emission levels.

Recent Publications:

1. Sayegh M., Danielewicz J., Nannou T., Miniewicz M., Jadwiszczak P., Piekarska K., Jouhara H. (2017) Trends of European research and development in district heating technologies. Renewable and Sustainable Energy Reviews 68: 1183-1192.

2. Ramos J., Chong A., Jouhara H. (2016) Experimental and numerical investigation of a cross flow air-to-water heat pipe- based heat exchanger used in waste heat recovery. International Journal of Heat and Mass Transfer 102: 1267-1281.

3. Jouhara H., Fadhl B., Wrobel L. (2016) Three-dimensional CFD simulation of geyser boiling in a two-phase closed thermosyphon. International Journal of Hydrogen Energy 41: 16463-16476.

4. Jouhara H., Milko J., Danielewicz J., Sayegh M., zulgowska- Zgrzywa M., Ramos J., S.P. Lester S. (2016) The performance of a novel flat heat pipe based thermal and PV/T (photovoltaic and thermal systems) solar collector that can be used as an energy - active building envelope material. Energy 108:148-154.

5. Danielewicz J., Åšniechowska B., Sayegh M., Fidorów N., Jouhara H. (2016) Three-dimensional numerical model of heat losses from district heating network pre-insulated pipes buried in the ground. Energy 108: 172-184.

6. Jouhara H., Szulgowska-Zgrzywa M., Sayegh M., Milko J., Danielewicz J., Nannou T., Lester S. (2016) The performance of a heat pipe based solar PV/T roof collector and its potential contribution in district heating applications. Energy

7. Amini A., Miller J., Jouhara H. (2016) An investigation into the use of the heat pipe technology in thermal energy storage heat exchangers. Energy