Day 2 :

Keynote Forum

Vance N. Owens

South Dakota State University, USA

Keynote: Potential yield of dedicated energy crops: results and outcomes of the sun grant regional feedstock partnership

Time : 10:10-10:45

Biography:

Vance Owens received BS, MS, and PhD degrees at Brigham Young University, Utah State University, and the University of Wisconsin-Madison, respectively. He is Director of the North Central Sun Grant Center and Professor of Plant Science at South Dakota State University. He has conducted research on production of bioenergy feedstock crops, specifically perennial species, for more than 20 years.

Abstract:

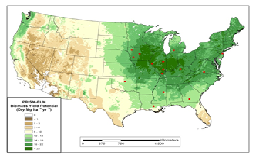

Statement of the Problem: The Sun Grant Regional Feedstock Partnership commenced in 2007 with the goal of supporting the realization of the biomass potential envisioned in DOE’s 2005 Billion Ton Report. Concluding in 2016, the partnership sought to increase the knowledge of bioenergy through coordinated feedstock research across the lower 48 states and Hawaii with partners in academia, government, and private industry. Methodology & Theoretical Orientation: The core of the research includes over 130 field trials and regional resource assessment activities focused on agricultural residues and a suite of likely dedicated energy crops. In 2013 a series of meetings was held across the US with each of the crop teams and the resource assessment team, led by the Oregon State University and Oak Ridge National Laboratory, to review, standardize, and verify yield trial data and assimilate their outcomes into a national model of biomass yield suitability. The meetings provided a way to “ground truth” yield estimates in order to accurately capture interactions of climate and soils for dedicated energy crops, including switchgrass, energycane, biomass sorghum, CRP mixtures, Miscanthus x giganteus, hybrid poplar, and willow. Findings: From these sets of funded trials and historical data, yield was estimated across spatial gradients according to soil characteristics and climate history (see Figure 1 for Giant Miscanthus example). The resulting spatial grids provide critical information for policymakers and planners of the potential productivity of these pre-commercial crops. National yield estimates, as well as overall yield across the continental USA, demonstrated potential for these diverse feedstock resources. Conclusion & Significance: Production and management data, as well as biomass composition characteristics, provide empirical support of logistic design and feedstock supply systems. These data and maps are vital for policy makers, producers, end-users, and others in the bioeconomy.

Recent Publications

1. D.K. Lee, 55 other authors, and V. Owens. 2017. Biomass Production of Herbaceous Energy Crops in the United States: Field Trial Results and Yield Potential Maps from the Multiyear Regional Feedstock Partnership. GCB Bioenergy (Accepted).

2. Liming Lai, Chang Oh Hong, Sandeep Kumar, Shannon L. Osborne, R. Michael Lehman and Vance N. Owens. 2017. Soil nitrogen dynamics in switchgrass seeded to a marginal cropland in South Dakota. GCB Bioenergy, doi:10.1111/gcbb.12475.

3. John H. Fike, James W. Pease, Vance N. Owens, Rodney L. Farris, Julie L. Hansen, Emily A. Heaton, Chang O. Hong, Hilary S. Mayton, Robert B . Mitchell and Donald R. Viands. 2017. Switchgrass nitrogen response and estimated production costs on diverse sites. GCB Bioenergy (2017), doi: 10.1111/gcbb.12444.

4. Arvid Boe, Paul J. Johnson, Vance Owens, DoKyoung Lee, Jia Guo, Jose L. Gonzalez- Hernandez. 2017. Genetics and Partitioning for Biomass of Prairie Cordgrass Compared to Switchgrass on Marginal Cropland. Bioenergy Research DOI 10.1007/s12155-017-9849-0.

5. Ibrahim, M., Chang Oh. Hong, S. Singh, S. Kumar, S. Osborne, and V. Owens. 2017. Switchgrass biomass quality as affected by nitrogen rates, harvest time, and storage. Agron. J. 109:1–11, doi:10.2134/agronj2016.07.0380.

6. Owens, V.N., D.R. Viands, H.S. Mayton, J.H. Fike, R. Farris, E. Heaton, D.I. Bransby, C.O. Hong. 2013. Nitrogen use in switchgrass grown for bioenergy across the USA. Biomass and Bioenergy http://dx.doi.org/10.1016/j.biombioe.2013.07.016.

Break:

Networking and Refreshments Break 10:45-11:05 @ Breakout Areas

Keynote Forum

Matjaz Kunaver

National Institute of Chemistry, Slovenia

Keynote: Biomass waste – A source of raw materials and nanocellulose

Time : 11:05-11:40

Biography:

Abstract:

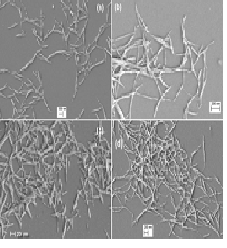

Cellulose containing Biomass represents an immense and renewable source for the production of bio-fuels and valuable chemicals. A little amount of this is used in industry and the remaining is leftover in huge quantities. Much effort has been devoted in converting these types of biomass into useful industrial and commercially viable products. In recent years, some effective processes have been found, such as thermochemical conversion producing several new products from these renewable resources. An overview of such applications and methods will be presented in this contribution. One of possibilities of converting biomass is the liquefaction. During liquefaction reaction, lignocellulosic components are depolymerized to low molecular mass compounds with high reactivity, high hydroxyl group content and can be used in many useful applications. A high energy ultrasound or microwaves can be used as an energy source to speed up the liquefaction process. The liquefied biomass was used as a feedstock in the synthesis of polyesters, polyurethane foams and adhesives. The same liquefaction process was used for the isolation of the nanocrystalline cellulose from biomass. The method is a novelty and a model procedure for NCC isolation from different natural cellulosic sources with high yields and with high crystallinity index. The process of

Cellulose containing Biomass represents an immense and renewable source for the production of bio-fuels and valuable chemicals. A little amount of this is used in industry and the remaining is leftover in huge quantities. Much effort has been devoted in converting these types of biomass into useful industrial and commercially viable products. In recent years, some effective processes have been found, such as thermochemical conversion producing several new products from these renewable resources. An overview of such applications and methods will be presented in this contribution. One of possibilities of converting biomass is the liquefaction. During liquefaction reaction, lignocellulosic components are depolymerized to low molecular mass compounds with high reactivity, high hydroxyl group content and can be used in many useful applications. A high energy ultrasound or microwaves can be used as an energy source to speed up the liquefaction process. The liquefied biomass was used as a feedstock in the synthesis of polyesters, polyurethane foams and adhesives. The same liquefaction process was used for the isolation of the nanocrystalline cellulose from biomass. The method is a novelty and a model procedure for NCC isolation from different natural cellulosic sources with high yields and with high crystallinity index. The process of

[1] Kunaver M, JasiukaitytÄ— E, ÄŒuk N (2012) Ultrasonically assisted liquefaction of lignocellulosic materials Bioresource Technology 103:360-366

[2] Kunaver M, Anžlovar A, Žagar E (2016) The fast and effective isolation of nanocellulose from selected cellulosic feedstocks Carbohydrate polymers 148:251-256

[3] Khalil H P S A, Bhat A H, Yusra A F I (2012) green composites from sustainable cellulose nanofibrils: a review Carbohydrate Polymers 87: 963-979

[4] Fan J, Li Y Maximazing the yield of nanocrystalline cellulose from cotton pulp fiber (2012) Carbohydrate Polymer 88:1184-1188

[5] Texeira et al. (2010) Cellulose nanofibers from white and naturally colored cotton fibers Cellulose 17: 595-606

Keynote Forum

Paul R James

Ramboll, United Kingdom

Keynote: GHG reduction options for coal fired power stations

Time : 11:40-12:15

Biography:

Paul R James is trained as a Chemist and in Chemical Engineering, Paul has spent some 25 years working in the Energy and Environment fields in both the Public and Private Sector.

His early career included managing Environment & Energy performance in the Pharmaceutical Sector, policy development and regulation of major industry in the UK and Europe, and latterly consulting on large scale energy and waste projects. He the Chairman of the UK Chartered Institute of Wastes Management (CIWM) Special Interest Group on Thermal Waste Treatment.

Abstract:

The presentation will provide an overview of developments in the energy supply market that are resulting in increased biomass co-firing and conversion of existing coal fired assets to use biomass. It will explain the policy and market conditions, as well as the technical adaptations, challenges and benefits associated with reducing GHG emissions using biomass, including several possible ways of significantly reducing the GHG foot print of a coal fired power station based on experienced and proven technological solutions from bioconversion projects executed over the last 20 years in Denmark. The presentation will present options based on two case studies, comprising the successful conversion of existing plants in the range from 100 MWe up to 500 MWe to biomass firing. The systems to be explained will briefly include fuel handling and preparation, combustion systems and boilers and display the differences between the options in capital expenditure and reduction in GHG emissions.